|

|

|

This site has moved to my own web server here please use it instead. Thanks!

The goal of the project was to design and build an affordable ignition

upgrade

for the MR2 Turbo (3S-GTE). The original plan was to build my

own ignition

circuits using the Motorola MC3334P chip, and four ignition coils (one

for each spark plug). The MC3334P chip has current limiting capability,

and the ability to automatically adjust dwell time. I did get

the car to run

with four coils, but the ignitor circuit kept overheating, and I, in

general,

had problems with it. The biggest challenge to the project was

designing

the digital logic to take the place of the stock distributor (ie a

spark plug

selection circuit).

The stock Toyota ECU (as it is on many Toyota's) uses a position sensor

in the distributor (G1) to determine the engine position. It

then adjusts

the timing based on various engine parameters and sends a signal (5

volt

pulse waveform) called IGT to the stock ignitor. The signal goes

high to

charge the coil, and then low to fire the coil. The stock ignitor

returns

a feedback signal to the ECU (called IGF) to tell the ECU that it

actually did fire. It is the IGT signal that needs to be modified

and

then sent to different ignitors/coils.

The first iteration of the circuit used a Flip Flop, Inverter, a comparater

(

for signal conditioning of IGT, and G1), and a 3 to 8 line decoder

(inverting).

This circuit did work, and the car ran with four coils, but there was

some problems

(as stated earlier) with the four ignitors.

Since the charge time could be so long for four coils, it was decided

to try to build a system using a 'wastespark' design with twin tower

coils. GM

uses this type of coil, as well as electromotive, and numerous other

manufactures

including the 1986-88 RX-7. These coils (RX-7 coils) in particular

are very powerful coils (ie

have a low primary resistance). The downside to these coils is

that, new, they cost

around $250.00. With ignitor they cost around $350.00.

Fortunately I found

a couple at a junk yard with ignitors for $70.00 (for two!).

It seems very likely

that the GM coils/ignitors could also have been used. I've been

told that the GM

coils can be had for around $30.00 - new.

The digital logic was then modified to fire just two coils instead

of four. Because of

the simplified operation, the G1 signal was not needed to make the

circuit work. It would,

however, probably be best to design a circuit that would use G1; however

no problems

have been found with the current setup. (new) - There is a slight

problem - every once in a while

during start up the circuit does not 'sync up' with the firing order

and the ignition has to be

turned off and restarted. This happens infrequently, and is easily

remided by just trying again.

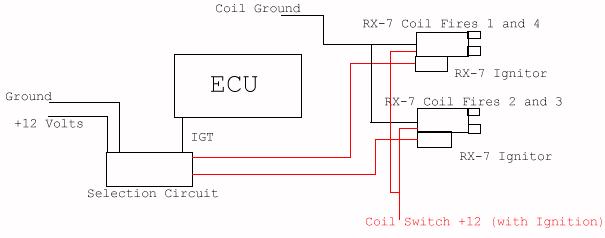

Here is a diagram (bad drawing sorry) of the setup:

The two coils (+12) are hooked to the stock wiring for the ignition.

There is a 40 amp (if

memory served) fuse for this circuit, which is plenty. The ground

for each coil was

wired to two separate ground locations using 12 gauge wire. The

wiring from the

selection circuit to the ignitor should be shielded, but does not have

to be very think - 18

gauge wire is plenty.

Up until now, I was taking the output of the stock coil (which would

normally go to the

distributor) and feeding it into a 4.7k resistor. This kept the

IGF signal happy as well

as the tachometer. However charging the additional coil didn't

really make sense. So

the MSD tach adapter (PN8910 HEI) was purchased from Summit Racing

for about $26.00.

This (basically coil) attaches to where the stock coil originally connected.

The nice thing

about this setup, is that switching back to the stock ignition is relatively

easy (if nice

connectors are used). I used bullet connectors from Radio Shack.

What about charge time?

The charge time for each coil is basically doubled from what it would

have normally

been with the stock ignitor/coil. The nice thing about this is

that even at 7200RPM

the coils should give a nice strong spark (each only 'sees' 3600RPM).

The bad thing

is that it is somewhat wasteful as the coils do not need to be charged

that long. I have

monitored coil temperature, and even after a long drive (45 minutes)

they are cool

to the touch.

Results

I do not have any concrete results yet. However, my 1991 MR2

turbo did have a hesitation

problem on cold starts on cold mornings. This is all but gone

with the new ignition! Gas mileage

improved from 18.00 to 18.7 (first try) - OK so that's not that big

a deal. I have new plugs

which I plan on running at a gap of 0.40 to see what happens.

There does seem to be more

high end punch - but that's seat of the pants speculation. Since

there are no spark plug

wires attached to the distributor, there will never be a need to change

the cap&rotor. The losses

(from the spark jumping from the rotor to cap) are elliminated since

it is now done electronically.

How do I build one

I've spent a long time designing this ignition - starting the engine,

looking at signals - over

and over etc.. The selection circuit is not built with a micrcontroller

- it is all 'in hardware',

and is wire wrapped for durability. The original plan was to

make an ignition kit that could

be purchased - but some more development needs to be done for that

(but hopfully soon!).

If you are interested in building a setup like this for your Toyota

- I'll be happy to help.

Just send me an email!

:-)

Joseph Obernberger